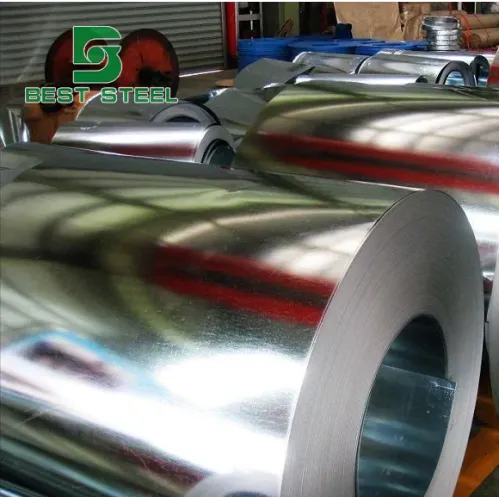

PPGI & GI Coil

PPGI & GI Coil Product Description PPGI sheet is the ultimate product for deep processing of sheet by steel companies in the world today. With light weight, beautiful appearance, good corrosion resistance, etc., it is widely used in construction, light industry, home appliances and other industries. During production, use a crane to roll up the raw materials on the receiving platform of the color coating unit, and then use a transport trolley to transport the steel coil to the coil seat in front of the color coating unit, remove the steel strip here, and then load the trolley to remove the raw steel The coil is loaded on the uncoiler, and the strip head is automatically guided to the cutting head by the belt guide device. The strip is sewn with the previous loop on the sewing machine. The stitched steel strip first enters the pre-cleaning section for alkaline water washing, alkaline water scrubbing, and hot water washing, and then enters the looper after being dried by hot air. A